Choosing the Right Freeze Protection for Your System: Basin Heaters, Heat Traces, or Indoor Sump Pumps

In This Article, You Will Learn:

- The difference between each freeze protection option for your cooling tower: cooling tower basin heaters, heat tracing, and indoor sump tanks.

- How to choose the best option for your cooling tower system.

- Ideal timing for installing or upgrading your freeze protection system.

Here's the scenario every facility manager dreads: the first unexpected cold snap of the year hits, and your facility's cooling tower—a critical piece of equipment—grinds to a halt.

A frozen tower isn't just an expensive, middle-of-the-night emergency repair. It's a direct threat to your operations, leading to costly downtime, permanent component damage, and potential safety risks.

Because cooling towers are designed to maximize water evaporation, they are incredibly vulnerable to freezing temperatures. The key to avoiding this disaster is a proactive strategy to prevent cooling tower freezing.

But there's no single "best" solution. The right choice for your facility depends on your climate, system design, and operational budget. In this post, we'll compare the three most effective and common methods to protect your investment: cooling tower basin heaters, heat tracing, and indoor sump tanks.

Understanding cooling tower freeze protection solutions starts with looking at what is out there and building your understanding from there.

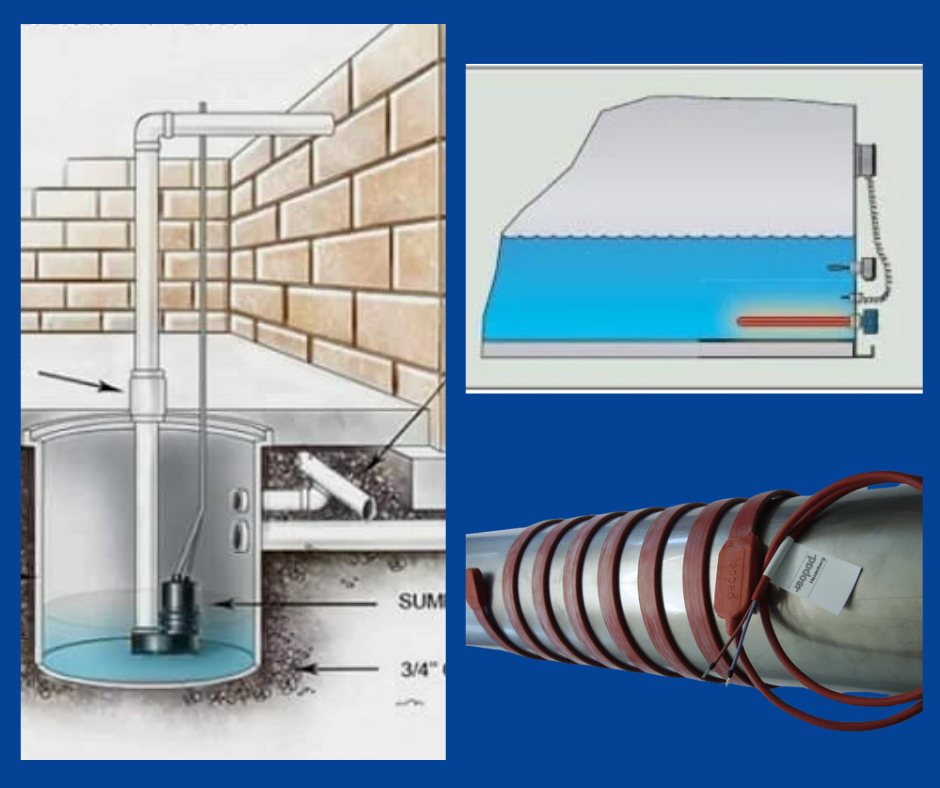

Method 1: Cooling Tower Basin Heaters

What They Are

Think of cooling tower basin heaters as robust, industrial-grade immersion heaters, similar in concept to the heating element in a water heater but built to withstand harsh tower environments. They are installed directly in the cold-water basin of your cooling tower.

How They Work

Basin heaters offer simple, effective freeze protection. Wired to a control panel with a thermostat, they activate automatically when water drops to about 40°F (4°C), heating the basin water just enough to prevent ice and protect the basin and water supply.

Pros

- Direct Protection: They directly heat the largest and most vulnerable volume of water in your system—the basin.

- Reliable & Simple: It's a proven, standard technology that is relatively simple to install and operate.

- Targeted: The integrated thermostat ensures they only consume energy when needed.

Cons

- Limited Scope: This is the most critical point to understand: Basin heaters only protect the water in the basin. They do nothing to protect your makeup water lines, drain lines, equalizer pipes, or fill, which can all freeze and crack.

- Energy Cost: In extremely cold climates or during prolonged cold snaps, they can consume a significant amount of electricity to keep the entire basin volume warm.

What are basin heaters best for? Facilities in moderate climates that experience infrequent or non-severe freezing conditions, or as the foundational component in a multi-layered protection plan (e.g., combined with heat tracing).

Method 2: Heat Tracing

What It Is

Heat tracing (often called "heat tape") is an advanced electric heating cable designed to be applied directly to the outside of pipes, valves, and other components. It's a targeted heating solution for the parts of your system most vulnerable to freezing.

How It Works

The heat tracing cable is carefully run along or wrapped around the pipes that need protection, such as makeup water lines, drain lines, and equalizer pipes. This cable is then covered with insulation to direct the heat inward. A controller, often with its own thermostat, sends electricity through the cable, which gently warms the pipe wall and prevents the water inside from freezing.

Pros

- Targeted Protection: It's the perfect solution for protecting your system's "arteries" and small-diameter pipes where water can sit and freeze quickly—areas that basin heaters can't reach.

- Versatile: It can be retrofitted onto most existing piping systems without major modifications.

- Completes the System: It's the ideal partner to a basin heater, protecting all the auxiliary piping that the basin heater misses.

Cons

- Specific Application: It is not designed to protect the main water in the cooling tower basin. You will still need a basin heater for that.

- Installation is Key: Requires careful installation. Any gaps in the heat tracing or, just as importantly, the insulation, can create a cold spot and lead to a failure point.

- Maintenance: The system must be regularly inspected and tested (often with an ohmmeter) to ensure the cable is intact and operational before the cold weather arrives.

What is heat tracing best for? It's an essential add-on to a basin heater system to provide complete protection. It's also used as a standalone solution for "dry sump" systems where the basin is drained, but the pipes still need to be protected.

Method 3: Indoor Sump Tanks (Remote Sump Systems)

What They Are

This is the most comprehensive freeze protection strategy. An indoor sump tank (also called a "remote sump") is exactly what it sounds like: a tank located inside your heated facility that holds the cooling tower's water. The outdoor basin is completely bypassed during cold weather.

How They Work

Instead of heating the outdoor basin water, the system reconfigures. When operating, water circulates normally. When the system shuts down or senses low-load/low-temp, outdoor basin water drains by gravity to an indoor sump, leaving the tower empty. System pumps then draw water from this protected indoor tank, ensuring they remain full of warm water and ready to restart.

Pros

- The Ultimate Protection: This method is the most effective way to prevent cooling tower freezing. By removing the water from the outdoor components, you eliminate the risk of freezing entirely.

- Highest Energy Efficiency (in harsh climates): You are no longer paying to heat a basin against frigid outdoor air. The water is protected by your building's existing heat, making it extremely efficient for facilities in very cold regions.

- Reduced Maintenance: It protects the tower basin from the wear and tear of continuous heating, freeze-thaw cycles, and potential heater-related corrosion.

Cons

- Highest Upfront Cost & Complexity: This is a major capital project. It requires significant engineering, extensive piping modifications, and a dedicated, large footprint inside your building.

- Space Requirement: You must have available, heated indoor space to locate a large tank.

- Not an Easy Retrofit: This solution is almost exclusively designed and installed with new cooling tower systems. Adding it to an existing tower is often prohibitively expensive and complex.

What are indoor sump tanks best for? Mission-critical facilities (like hospitals, data centers, or 24/7 manufacturing plants) in severe-weather climates where operational failure is not an option. It is the gold-standard solution, primarily for new construction.

How to Choose - A Side-by-Side Comparison

Choosing the right strategy depends on three key factors: your climate, your facility's operational needs, and your budget.

Here’s a simple guide to help you decide:

- You're in a moderate climate with rare, mild freezes: A Cooling Tower Basin Heater is a reliable, cost-effective baseline to prevent catastrophic ice formation in your basin.

- You have a basin heater, but worry about pipes: You absolutely need Heat Tracing. This is the essential add-on to protect your makeup lines, drains, and equalizer pipes, which are the most common failure points.

- You're in a harsh climate with deep, prolonged freezes: A combined system of Basin Heaters + Heat Tracing is the standard for robust protection on an existing tower.

- You are building a new facility OR have a mission-critical operation (like a hospital or data center) in a harsh climate: An Indoor Sump Tank is the gold-standard solution. The upfront cost is higher, but it offers the most complete protection and the best long-term energy efficiency.

The most common and effective retrofit solution is a combination of a basin heater to protect the bulk water and heat tracing to protect the plumbing.

Don’t Wait for the First Freeze

Proactive freeze protection isn't just an expense—it's an insurance policy against costly downtime, emergency repairs, and catastrophic equipment failure. A cracked pipe or a frozen basin can shut down your entire operation.

The right solution for you is the one that provides peace of mind all winter long. At Landover Cooling Tower Services, our expert technicians can assess your specific system, climate risk, and operational needs to design a freeze protection strategy that fits your facility and your budget.

Don't leave your system's health to chance. Contact us today for a comprehensive freeze protection assessment and prevent cooling tower freezing before the temperature drops.